Why Choose a Hydraulic Hose for Sale to Boost Your Project?

Choosing the right components for your project can significantly affect its success. Hydraulic hoses play a critical role in fluid conveyance. According to industry reports, the hydraulic hose market is projected to reach $8.3 billion by 2027, reflecting its essential presence in construction and manufacturing sectors.

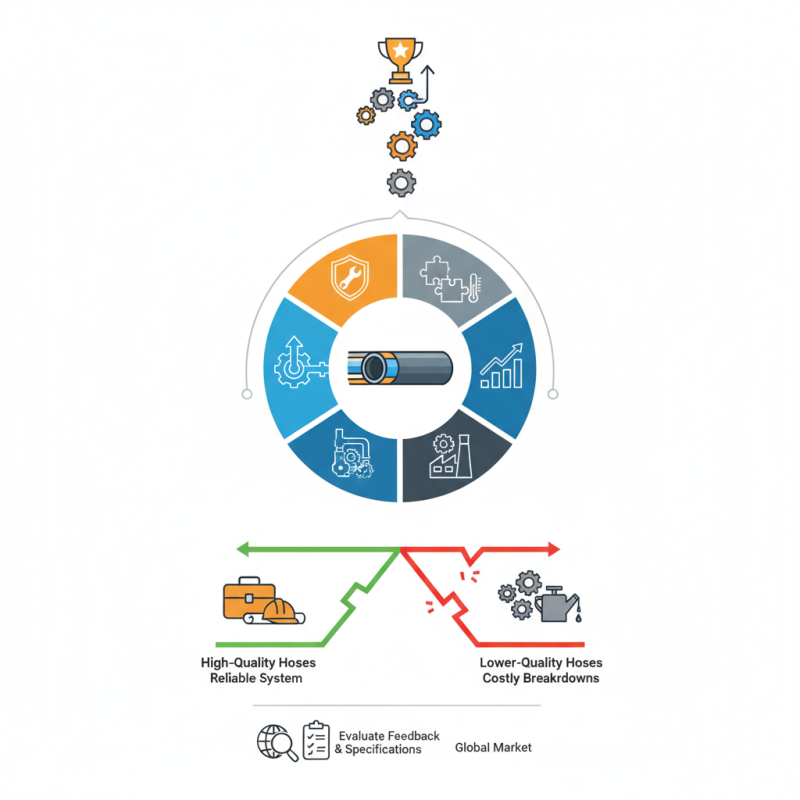

When searching for a "hydraulic hose for sale," consider durability and compatibility. High-quality hoses withstand extreme pressure and temperature fluctuations. A reliable hydraulic system improves operational efficiency. However, opting for lower-quality hoses can lead to costly breakdowns. This highlights the importance of making informed choices.

While the benefits are clear, not all suppliers provide the same standards. Evaluating feedback and specifications is crucial. In the end, the right hydraulic hose can elevate your project's performance. It's worth investing time to find the best options available. The implications of this choice extend beyond the immediate project.

Advantages of Hydraulic Hoses in Industrial Applications

Hydraulic hoses play a crucial role in various industrial applications. Their ability to withstand high pressure makes them ideal for transporting fluid in heavy machinery. These hoses are designed for efficiency and durability. They can handle extreme temperatures, ensuring reliable operation in challenging environments.

One major advantage is flexibility. Hydraulic hoses can bend and twist as needed, fitting easily into tight spaces. This adaptability can enhance the overall design of machinery. However, improper installation can lead to failures. It’s essential to ensure that connections are secure and the hoses are not subjected to excessive stress.

Maintenance is also vital. Regular inspections can catch small issues before they escalate. A worn or damaged hose can lead to leaks, which hinder productivity. Ignoring these signs often results in costly repairs and downtime. For anyone involved in industrial projects, understanding the proper use and care of hydraulic hoses is essential. The benefits they provide are substantial, but they require attention to detail to maximize their potential.

Key Features to Consider When Selecting a Hydraulic Hose

When selecting a hydraulic hose, you must consider several key features. The pressure rating is vital. It determines the maximum pressure the hose can withstand. If you choose a hose with a lower rating, it can burst. This leads to potential project delays and increased costs.

Flexibility also plays an essential role. A more flexible hose can bend easily without kinking. This is especially important in tight spaces. However, too much flexibility can reduce durability. It's a balancing act. Additionally, the hose's construction material influences its performance. Rubber hoses are often used for their resilience. Yet, they might not fare well in extreme temperatures.

Another factor is the hose diameter. You need the right size for your project. A larger diameter can allow higher flow rates, but it may not fit in tight spots. It's crucial to analyze your specific needs. In the end, selecting a hydraulic hose requires careful thought. Missteps can lead to inefficiencies. Testing different hoses before finalizing your choice may save future headaches.

Comparative Analysis: Hydraulic Hoses vs. Other Hose Types

Hydraulic hoses are essential in various industries, including construction and manufacturing. They are specifically designed to handle high-pressure applications, delivering fluids efficiently. In contrast, standard garden hoses or air compressor hoses cannot withstand such pressures. According to industry data, hydraulic hoses can typically handle pressures between 3,000 to 6,000 PSI, depending on their construction.

When comparing hydraulic hoses to other types, the differences are striking. For example, rubber hoses are versatile but prone to wear under pressure. Research indicates that improper materials can lead to hose failures, causing safety hazards. The flexibility of hydraulic hoses also facilitates installation in tight spaces, which can improve workflow in complex projects, while traditional hoses may require more space and additional fittings.

Moreover, hydraulic hoses often have superior resistance to temperature extremes and chemicals. They maintain performance in harsh conditions. Many users overlook this feature, which can lead to premature failure. Even seemingly minor flaws in hose quality can compromise a project. Industry experts recommend regular inspections to ensure optimal function. Understanding these aspects can help teams make better decisions for their projects.

How Hydraulic Hoses Enhance Project Efficiency and Durability

Hydraulic hoses play a crucial role in enhancing project efficiency. They provide a reliable means of transferring power through fluid. This is vital in construction, manufacturing, and agriculture. Well-designed hoses minimize downtime caused by leaks or failures. Higher durability translates to less frequent replacements. A broken hose can stop production and waste time.

Choosing the right hydraulic hose is essential. It should withstand pressure and temperature extremes. Poor-quality hoses can lead to unexpected failures, affecting the entire project. Additionally, the installation process matters. A poorly installed hose loses efficiency. Regular maintenance is crucial to ensure performance. Inspecting hoses can prevent future issues.

Efficiency isn't just about tools. It's about how those tools work together. Hydraulic hoses must integrate seamlessly with other equipment. Compatibility affects performance. While they enhance productivity, improper usage can hinder progress. Understanding the specifications is key. A small oversight can lead to big problems later.

Maintenance Tips for Prolonging the Life of Hydraulic Hoses

Hydraulic hoses are essential in various projects. Proper maintenance ensures their longevity. Regular inspections are necessary to catch wear and tear early. Look for signs of fraying or cracking. These issues may seem minor but can lead to significant failures later.

Another crucial aspect is cleanliness. Contaminants can harm the hydraulic fluid, affecting performance. Always ensure the fittings and hoses are free from dirt and debris. Consider using protective coverings when hoses are not in use.

Occasionally, check the connections. Loose fittings can lead to leaks. Ensure all connections are tight, but avoid over-tightening. It's a balance that requires attention. Remember, even small mistakes in hose care can lead to larger problems down the line.