Top 10 Benefits of Using Stainless Steel Wire Mesh?

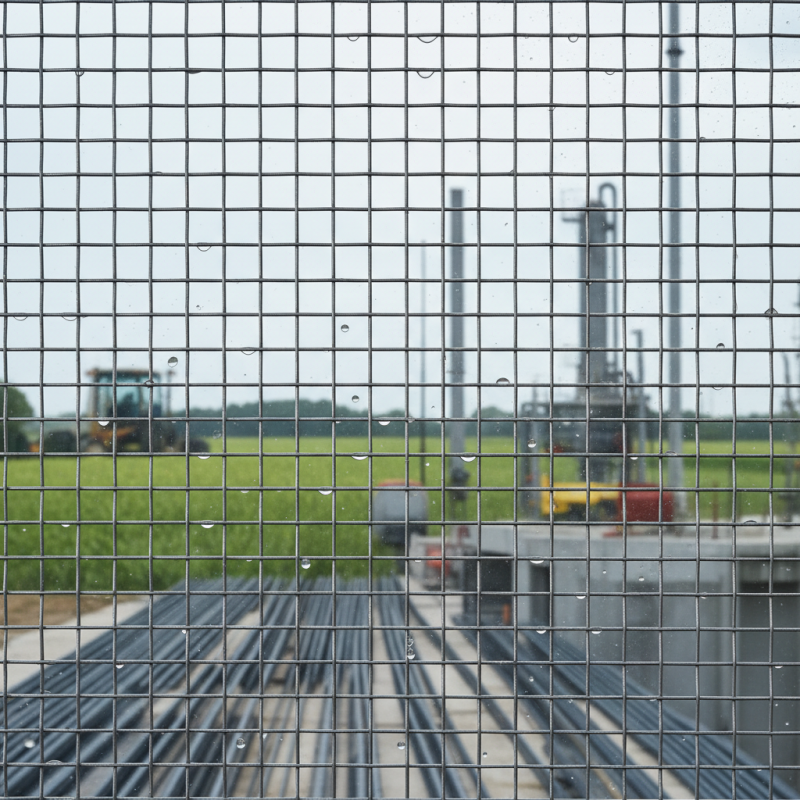

stainless steel wire mesh is a versatile material with numerous advantages. It is widely used in various industries, from construction to food processing. The strength and durability of stainless steel wire mesh make it an ideal choice for many applications.

One of its most significant benefits is corrosion resistance. This feature ensures longevity, even in harsh environments. Industries appreciate that maintenance is minimal with stainless steel wire mesh. It also provides excellent filtration, making it popular in agricultural and chemical sectors.

However, not all applications are straightforward. Occasionally, users face challenges in selecting the right specifications. It can be overwhelming to navigate the options available. Understanding the unique characteristics of stainless steel wire mesh is essential. Despite some complexities, its benefits far outweigh the challenges.

Advantages of Corrosion Resistance in Stainless Steel Wire Mesh

Stainless steel wire mesh is gaining popularity due to its exceptional corrosion resistance. This is vital in many industries, including food processing and construction. According to a report from the Stainless Steel Institute, stainless steel can withstand harsher environments than other metals. For example, it resists corrosion from saltwater and chemical exposure. This durability helps maintain product integrity and reduces replacement costs.

The unique properties of stainless steel wire mesh make it ideal for various applications. Its strength allows it to support heavy loads while remaining lightweight. Many industries value this benefit, as efficiency is crucial. Additionally, stainless steel does not rust, which helps preserve its appearance over time. This longevity saves both time and money, yet some users overlook how crucial maintenance is in ensuring its longevity.

However, it's important to note that stainless steel wire mesh isn't entirely maintenance-free. External factors, such as harsh chemicals, can still affect it. Regular inspections are essential to catch early signs of wear. Some users may miss these checks, leading to unforeseen problems. By being proactive, industries can maximize the advantages offered by stainless steel wire mesh.

Durability and Longevity of Stainless Steel Wire Mesh Applications

Stainless steel wire mesh is known for its impressive durability. It can withstand harsh conditions, making it ideal for various applications. This material resists corrosion, rust, and oxidation. Its strength allows it to hold up under pressure. Whether used in construction, agriculture, or filtration, its longevity shines through.

In many environments, stainless steel mesh performs remarkably well. For instance, in wet or humid areas, it reduces the risk of wear and tear. However, it is essential to select the right grade for the specific application. Some may choose lower-quality variants, leading to unexpected failures. Careful consideration ensures optimal performance and durability.

Additionally, stainless steel wire mesh requires minimal maintenance. Regular cleaning can enhance its lifespan. Though it might seem simple, neglect can lead to rust spots over time. Investing time in maintenance pays off in the long run. It's crucial to remain aware of the mesh's condition, adapting as needed.

Versatile Applications of Stainless Steel Wire Mesh in Various Industries

Stainless steel wire mesh has gained popularity across diverse industries. Its versatility shines in construction, offering robust support while ensuring durability. Builders often use it for reinforcing concrete and other structures, which adds strength without adding excessive weight.

In the food processing sector, stainless steel wire mesh is essential. It is perfect for filters and screens, ensuring products remain free from contaminants. The mesh's resistance to corrosion makes it suitable for harsh environments, yet its delicate weave allows for optimal air circulation.

The automotive industry also finds value in stainless steel wire mesh. It is used for exhaust systems and filters, ensuring efficient airflow. Innovators experiment with different mesh sizes, adjusting them for unique applications. There are challenges, though. Finding the right balance between durability and flexibility can be tough. Some engineers may overlook this, leading to suboptimal performance.

Maintenance and Cleaning Benefits of Stainless Steel Wire Mesh

Stainless steel wire mesh is known for its remarkable durability. It resists corrosion, rust, and wear. This makes it an ideal choice across industries. Regular maintenance is simple. Just a quick rinse with water removes dirt and debris. For deeper cleaning, mild soap works wonders. Interestingly, reports suggest that stainless steel can last over 30 years with proper care.

Cleaning stainless steel wire mesh doesn't require harsh chemicals. This is environmentally friendly and safe for users. According to a study by the International Stainless Steel Forum, stainless steel's non-porous surface reduces bacterial growth. Fewer bacteria mean a cleaner environment. However, some users overlook the need for periodic inspections. Checking for buildup can enhance the mesh's lifespan.

Some might underestimate how easy cleaning can be. A little effort goes a long way. Stains can appear if neglected, which is frustrating. Keeping up with maintenance is crucial. Ultimately, stainless steel wire mesh offers both functionality and ease of care. This balance is why it's popular in diverse settings.

Top 10 Benefits of Using Stainless Steel Wire Mesh

The bar chart above illustrates the top 10 benefits of using stainless steel wire mesh. Each benefit is rated on a scale of 1 to 10, highlighting features such as its exceptional corrosion resistance, durability, and low maintenance requirements, making it a preferred choice in various applications.

Aesthetic Appeal and Design Flexibility of Stainless Steel Wire Mesh

Stainless steel wire mesh is more than just a functional material. Its aesthetic appeal is significant in modern design. This type of mesh comes in various patterns and finishes, allowing designers to create unique visual effects. According to a recent industry report, over 70% of designers prefer stainless steel for its versatility in aesthetics. Architects often specify stainless steel wire mesh for facades, railings, and decorative applications.

The adaptability of stainless steel wire mesh is notable. It can be woven in different sizes and shapes. This flexibility makes it suitable for both contemporary and traditional styles. For instance, fine mesh offers a sleek look, while larger openings can create a more rustic feel. Moreover, its reflective quality enhances natural light in spaces. In fact, studies show that buildings with wire mesh facades use up to 20% less energy by maximizing daylight.

However, it's important to recognize some limitations. While stainless steel is durable, its initial cost can deter some projects. Not all projects require its high performance, which could lead to overinvestment in some cases. In addition, maintenance is crucial. In humid environments, corrosion can occur if not cared for properly. This highlights the need for thoughtful selection and application in design.